A washer is a flat, spherical piece of hardware with a hole in the center that is frequently used to increase tension between a screw or nut and a surface. One such piece of hardware that was created from rubber is a washer. A rubber washer is most frequently employed in situations where a tight seal, with some give in the washer, and exposure to liquids like water or humidity are necessary. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to military applications we build trust by being responsive to your needs.

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

All your typical molded rubber parts & more! Our custom rubber molding expertise includes mold conversion, non-conductive parts, injection molding, compression molding, transfer molding, die cutting & extrusions, plus cryogenic deflashing, trimming and curing. Low to medium volumes on time & budget!

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both domestic and offshore services are available.

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO 9001:2015 & AS 9100-D. Collaborative product customization available. Request free samples on site.

National Rubber was founded in 1997 with the values of variety, consistency, quality, open communication, and timely delivery at its core. Today, we stay true to these values by taking each one of your specifications into consideration, and working with you through every step of the manufacturing process. Call us today for more information!

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Washer Companies

Rubber Washers: Comprehensive Guide to Features, Types, Applications, and Sourcing

Rubber washers are essential components in a wide array of mechanical assemblies and industrial applications. They serve as highly effective seals, buffers, and vibration dampeners, significantly improving the performance and longevity of fastened joints. Whether you’re a procurement manager searching for bulk rubber washers for manufacturing, an engineer specifying materials for a new project, or a DIY enthusiast looking to improve waterproofing and insulation, understanding the full spectrum of rubber washer capabilities and options is crucial.

What Is a Rubber Washer?

A rubber washer is a flat, ring-shaped device typically made from elastomeric materials such as silicone, neoprene, EPDM, or natural rubber. It features a central hole that allows a screw, bolt, threaded pipe, or conduit to pass through its middle during installation. The size of the central hole is intentionally designed to be smaller than the corresponding nut, head, or fastener, while the overall diameter of the washer is greater than the fastener head. This design ensures the washer is firmly held in place, providing a stable seal and distributing mechanical loads evenly across surfaces. Rubber washers are favored for their remarkable flexibility, water resistance, non-conductivity, and vibration absorption—making them indispensable in both industrial and consumer applications.

How Are Rubber Washers Manufactured?

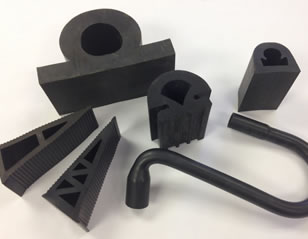

Rubber washer manufacturing is a precision process that varies according to the specific performance requirements of the final product. The two most common manufacturing techniques in the rubber fabrication industry are compression molding and injection molding.

Injection Molding Process

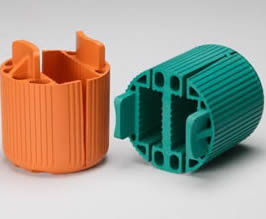

Injection molding is a highly efficient method used to produce uniform, high-volume batches of rubber washers. During this process, raw rubber material is heated until molten and then injected under pressure into a mold cavity precisely shaped like the desired washer. The molten rubber fills the cavity, conforming to every contour, and is then cooled and solidified. This technique is especially beneficial for custom rubber washers that require tight tolerances and consistent quality, making it the preferred choice for industries such as automotive manufacturing, electronics, and plumbing.

Compression Molding Process

Alternatively, compression molding involves placing a pre-measured amount of uncured rubber material into a heated mold cavity. The mold is then closed, and pressure is applied, forcing the rubber to flow and fill the cavity completely. Once the material has cured and set, the mold is opened, and the finished washer is removed. Compression molding is ideal for producing thicker, more complex washer profiles and is often used for low- to medium-volume production runs.

Pro Tip: Both molding processes can be used to manufacture washers in a wide variety of shapes, sizes, and rubber compounds, ensuring the finished product meets precise application requirements. For large-scale or specialized projects, manufacturers may also offer die cutting and water jet cutting services to produce custom rubber washers quickly and efficiently.

Key Types of Rubber Washers and Their Properties

Choosing the right type of rubber washer is essential for maximizing performance in your application. The choice depends on required properties such as temperature resistance, chemical compatibility, flexibility, and environmental exposure. Here, we outline the most commonly used rubber washer materials and their characteristics.

Silicone Rubber Washers

Silicone rubber washers are renowned for their ability to withstand extreme temperatures, making them suitable for both high-heat and cold environments. These washers remain flexible and durable at temperatures ranging from approximately -150°F to 500°F (-100°C to 260°C). Thanks to their excellent resistance to ultraviolet (UV) radiation, ozone, and fungal growth, silicone washers are frequently used in food processing, medical devices, and outdoor electrical enclosures. While they are not recommended for use with petroleum oils and ketones, they are compatible with many other chemicals, including braking fluids and high-aniline point oils.

- Temperature Range: -150°F to 500°F

- Best For: Food-grade applications, medical equipment, electronics, outdoor use

- Limitations: Not suitable for use with petroleum-based products

EPDM Rubber Washers

Ethylene propylene diene monomer (EPDM) rubber washers offer exceptional resistance to weather, ozone, steam, water, and a wide range of chemicals. With a working temperature range of -60°F to 280°F, EPDM washers are ideal for outdoor, automotive, HVAC, and plumbing applications. They feature low gas permeability and excellent dielectric properties, making them suitable for electrical insulation. EPDM also provides outstanding color stability and maintains its properties even after prolonged exposure to sunlight and heat.

- Temperature Range: -60°F to 280°F

- Best For: Outdoor equipment, automotive weather seals, HVAC systems, electrical insulation

- Limitations: Not compatible with most oils and hydrocarbons

Neoprene Rubber Washers

Neoprene rubber washers are highly valued for their balanced combination of oil, solvent, and ozone resistance. These washers perform reliably in temperatures from -65°F to 260°F and exhibit strong resistance to weathering, moderate acids, high-aniline point oils, and refrigerants such as Freon. Their durability and versatility make them a go-to choice for automotive, marine, and industrial sealing applications, as well as in HVAC and refrigeration systems.

- Temperature Range: -65°F to 260°F

- Best For: Automotive assembly, marine equipment, refrigeration, HVAC, general industrial sealing

- Limitations: Limited chemical resistance to strong acids and some hydrocarbons

Other Common Rubber Washer Materials

- Natural Rubber: Offers superior elasticity and tensile strength; best for applications with moderate temperature and chemical exposure.

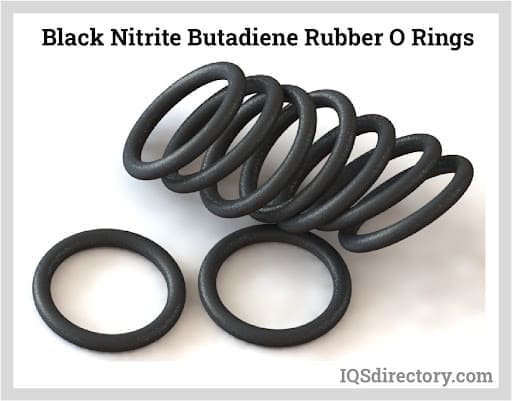

- Nitrile (Buna-N): Highly resistant to oils, fuels, and greases; popular in fuel systems and hydraulic sealing.

- Viton® (FKM): Excellent chemical and heat resistance; ideal for aerospace, automotive, and chemical processing industries.

Benefits of Using Rubber Washers in Your Application

Rubber washers deliver a host of advantages over metal, plastic, and fiber alternatives. Their unique performance characteristics are essential in ensuring the longevity, safety, and functionality of mechanical assemblies and equipment.

- Water and Fluid Resistance: Rubber washers are impervious to water, making them ideal for plumbing, irrigation, and marine applications where waterproof seals are critical. Their resistance to a wide range of fluids—including oils, alcohols, and mild acids—ensures leak prevention and long-term durability.

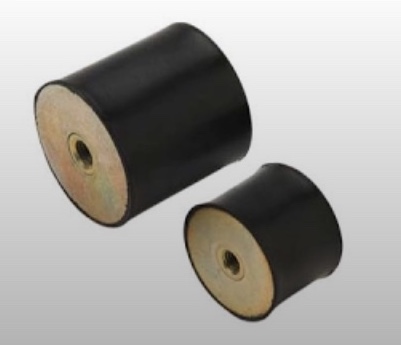

- Vibration and Noise Dampening: The inherent elasticity of rubber absorbs mechanical vibrations and reduces noise transmission, protecting sensitive components and enhancing user comfort in appliances, vehicles, and machinery.

- Electrical Insulation: Many rubber compounds are non-conductive, providing crucial isolation in electrical and electronic assemblies where short-circuit risks must be minimized.

- Corrosion and Rust Prevention: Unlike metal washers, rubber washers do not corrode or rust, even in harsh or humid environments. This eliminates concerns about contamination, surface damage, or premature failure caused by oxidation.

- Flexibility and Easy Installation: The pliability of rubber allows for simple installation and effective sealing, even when surfaces are uneven or fasteners are slightly misaligned.

- Cost-Effectiveness: Rubber washers are affordable and require minimal maintenance, resulting in lower total cost of ownership over the lifecycle of the equipment.

- Chemical Resistance: With the right material selection, rubber washers can withstand exposure to industrial chemicals, solvents, and fuels, making them suitable for a diverse array of environments.

Common Applications for Rubber Washers

The versatility of rubber washers makes them indispensable across dozens of industries and use cases. Their sealing, damping, and insulating properties are leveraged in countless products and systems, including:

- Plumbing and Pipe Fittings: Ensure leak-proof connections in faucets, valves, toilets, and irrigation systems.

- Automotive and Transportation: Dampen vibrations and prevent fluid leakage in engines, transmissions, fuel systems, and exhaust assemblies.

- Electronics and Electrical: Isolate sensitive circuit boards, prevent electrical shorts, and provide moisture sealing in enclosures and switches.

- HVAC and Refrigeration: Seal and cushion joints in air conditioning, heating, and cooling equipment.

- Appliances: Improve noise control and prevent water leaks in washing machines, dishwashers, refrigerators, and other household equipment.

- Construction and Roofing: Provide weatherproof seals for windows, doors, and roofing fasteners.

- Marine and Outdoor Equipment: Withstand exposure to saltwater, sun, and harsh weather in boats, docks, and outdoor assemblies.

- Medical Devices: Ensure sanitary, leak-free connections in diagnostic machines, tubing, and fluid delivery systems.

- Industrial Machinery: Absorb impact and seal joints in manufacturing equipment, pumps, and compressors.

How to Select the Right Rubber Washer for Your Project

Choosing the optimal rubber washer involves evaluating several key decision factors to ensure reliability, safety, and long-term value. Here’s a helpful checklist to guide your selection process:

- Material Compatibility: Will the washer come into contact with specific chemicals, oils, or fluids? Match the rubber compound to your environment (e.g., EPDM for water, nitrile for oils).

- Temperature Range: Consider minimum and maximum operating temperatures. Select silicone for extreme temperature swings or neoprene for moderate conditions.

- Mechanical Load: Assess the compressive and tensile forces the washer must withstand to avoid premature deformation or failure.

- Installation Environment: Will the washer face outdoor elements, UV exposure, or submersion? Choose compounds like EPDM or silicone for weather resistance.

- Electrical Insulation: For applications involving electricity, verify that the washer material is non-conductive and meets relevant safety standards.

- Size and Customization: Do you require standard or custom dimensions? Many manufacturers offer precise die-cutting or molding services for unique sizes and shapes.

- Certifications: For food-grade, medical, or aerospace applications, ensure the washer meets necessary regulatory and quality certifications (e.g., FDA, NSF, ISO).

Explore More: What Size Rubber Washer Do I Need?

Not sure which washer size or thickness is right for your application? Explore our comprehensive sizing guide or use our washer sizing calculator to determine the perfect fit for your requirements. Contact our technical support team for expert advice on selecting the right dimensions and tolerances.

How to Source Rubber Washers: Finding the Right Manufacturer

When it comes to purchasing rubber washers, selecting a reputable and experienced manufacturer is essential for ensuring consistent quality, reliable delivery, and competitive pricing. Here’s how you can streamline your sourcing process:

- Research Multiple Suppliers: Compare at least four different rubber washer manufacturers using our curated manufacturer directory. Evaluate each company’s product range, capabilities, and customer reviews.

- Review Business Profiles: Each supplier’s profile page highlights areas of expertise, custom manufacturing capabilities, and technical certifications. Use our patented website previewer to quickly assess their offerings.

- Request Quotes: Utilize our simple RFQ (Request for Quote) form to send your requirements to multiple suppliers simultaneously and receive competitive pricing.

- Contact for Customization: If your project requires non-standard sizes, materials, or performance characteristics, reach out to suppliers directly to discuss custom molding or die-cutting solutions.

- Verify Certifications: For mission-critical applications, verify that your selected manufacturer meets industry standards such as ISO 9001, FDA, or NSF certifications.

Ready to Request a Quote or Samples?

Take the next step in your procurement process:

- Visit our rubber washer manufacturer directory to shortlist suppliers.

- Use our RFQ form to submit your project details and receive customized quotes.

- Contact our technical team for expert advice on material selection, application engineering, and cost optimization.

Frequently Asked Questions About Rubber Washers

What are the main differences between rubber washers and metal washers?

Rubber washers provide flexibility, excellent sealing, electrical insulation, and resistance to corrosion and vibration, while metal washers offer higher mechanical strength and are better suited for high-load applications. The choice depends on your application’s environmental and mechanical requirements.

Are rubber washers reusable?

Many rubber washers can be reused if they have not experienced excessive compression, chemical degradation, or deformation. However, for critical sealing applications, it’s often recommended to replace washers during maintenance to ensure optimal performance.

How do I store rubber washers to extend their shelf life?

Store rubber washers in a cool, dry, and dark environment, away from direct sunlight, ozone sources, and extreme temperatures. Avoid storing near chemicals or solvents that could degrade the rubber material.

Can I order custom rubber washers in small quantities?

Yes. Many manufacturers offer custom rubber washer solutions with low minimum order quantities. Customization options include material selection, dimensions, thickness, hardness (durometer), and color.

What certifications should I look for when buying rubber washers for specialized applications?

Look for certifications such as ISO 9001 (quality management), FDA (food and medical use), NSF (drinking water safety), or UL (electrical safety), depending on your industry’s requirements.

Conclusion: Why Rubber Washers Are the Smart Choice

Rubber washers are an indispensable solution for reliable sealing, vibration control, and electrical insulation in countless industrial, commercial, and residential settings. Their broad material selection, customization capabilities, and cost-effectiveness make them the preferred choice for engineers, maintenance professionals, and manufacturers worldwide. By understanding the types, benefits, and sourcing strategies for rubber washers, you can make informed decisions that lead to enhanced equipment performance, longer service life, and lower maintenance costs.

Looking for more information?

- Explore our application guides for detailed use cases and industry-specific recommendations.

- Use our FAQ section to get answers to common questions about washer selection, installation, and maintenance.

- Connect with our technical support team for personalized assistance and sample requests.

- Browse our product catalog to discover the full range of standard and custom rubber washer solutions.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services