Rubber molding manufacturing involves shaping raw rubber materials into functional products. Rubber molding is an operation in which raw melted rubber takes form inside a mold.

While some products can be made by other rubber shaping processes such as cell casting and extrusion, the molding process has its own features that set it apart. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to military applications we build trust by being responsive to your needs.

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both domestic and offshore services are available.

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO 9001:2015 & AS 9100-D. Collaborative product customization available. Request free samples on site.

National Rubber was founded in 1997 with the values of variety, consistency, quality, open communication, and timely delivery at its core. Today, we stay true to these values by taking each one of your specifications into consideration, and working with you through every step of the manufacturing process. Call us today for more information!

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Molding Companies

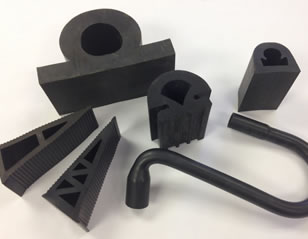

Products made through rubber molding are formed within a mold cavity rather than a die, allowing for the creation of intricate and irregular shapes. This fundamental difference enables manufacturers to produce highly detailed parts and components that meet the rigorous demands of modern industry.

Rubber Molding Applications

Molded rubber products play a crucial role in nearly every industry. From medicine and healthcare to electronics, aerospace, automotive manufacturing, and transportation, their applications are vast and ever-expanding. Rubber molding is also essential in sectors such as sports and recreation, industrial machinery, EMI shielding, sound management, and energy production.

The rubber molding process is the cornerstone of countless products, renowned for its precise and reliable results. Custom rubber molded components can be tailored to seamlessly integrate with any equipment, ensuring leak-free performance and long-lasting durability. The advent and versatility of synthetic rubber have broadened rubber molding applications across industries, including healthcare. This innovation allows for safer alternatives, such as latex-free materials suitable for individuals with latex allergies, and silicone tubing that safely carries intravenous fluids, thereby mitigating the risk of allergic reactions.

Products Produced from Rubber Molding

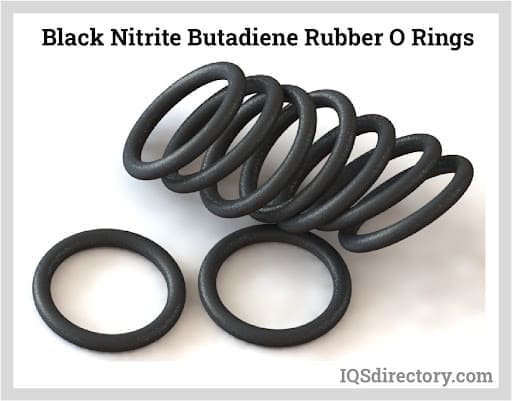

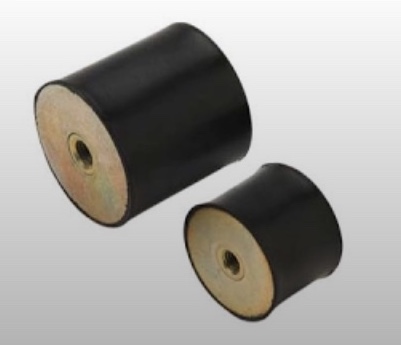

A wide variety of intricate rubber products are crafted through this process, supporting diverse industry needs. Notable examples of molded rubber parts include components for oil and gas, fluid pumps, rubber diaphragms, custom buttons, vibration absorbers and isolators, rubber seals, grommets, washers, bushings, cable boots, EMI shielding products, surgical instrument parts, blood analysis machine components, keypads, electrical connector inserts, and rubber sheets. Molded rubber is also used for O-rings, bellows, hoses, anti-vibration mounts, and protective covers.

Rubber Grommets

Rubber grommets serve as versatile components widely utilized across industrial, consumer, and commercial applications. Designed to encircle a hole in a surface, they safeguard wires or other hardware that pass through, while also protecting the hole from wear and damage. These grommets can be found ensuring wires stay securely connected, or neatly aligning desk holes for the safe passage of computer cables. In addition, they are crucial in automotive wire harnesses, machinery panels, and electronic devices.

Rubber Washers and Rubber Bushings

Given the potential for excessive vibrations in many manufacturing machines due to their moving parts, rubber washers and bushings are installed to stabilize these components and absorb the vibrations, thereby ensuring the safety of the operators. These components are also essential in automotive suspension systems, industrial equipment, HVAC units, and appliances to reduce wear and prolong service life.

Rubber Sheet

A rubber sheet, when placed beneath a machine, acts as a substantial, thick barrier that diminishes vibrations and noise. This reduction significantly enhances both safety and working conditions. Rubber sheets are also used in flooring, gaskets, sealing applications, and as impact-resistant surfaces in gyms and industrial environments.

History of Rubber Molding

Natural rubber’s use dates back millennia, with evidence suggesting South American tribes have utilized rubber tree sap to craft household items for thousands of years. Additionally, the Mayans are believed to have employed rubber as early as 1600 BC. However, the molding of rubber became practical only after the advent of vulcanization. This scientific breakthrough enabled the processing of rubber without degradation, revolutionizing its applications and making modern rubber molding techniques possible.

Before the advent of vulcanization, early attempts with rubber proved largely futile. The story starts in 1823, when Scottish chemist Charles Macintosh stumbled upon a breakthrough: blending rubber with a coal-tar derivative to bond it to fabric. This discovery rapidly popularized rubber products throughout Europe and the United States. However, users soon encountered persistent issues: aside from erasers and shoe soles, rubber frequently decayed swiftly, emitted unpleasant odors, and turned sticky in warm temperatures.

In 1839, the trajectory shifted when American innovator Charles Goodyear mastered the art of rubber vulcanization. By introducing sulfur to latex rubber, he stabilized the polymers, transforming rubber into a resilient material. His patent for this revolutionary process was granted in 1844. Despite its initial slow uptake, vulcanization gained momentum after 1889, spurred by the manufacture of rubber bicycle and automobile tires. By the early 1900s, global demand for rubber surged, prompting advancements in synthetic rubber compounds. Today, natural rubber accounts for less than half of all rubber produced worldwide—a testament to the evolution and importance of synthetic rubber manufacturing.

In 1872, brothers Isaiah and John Hyatt secured a patent for the pioneering rubber injection molding machine. Throughout the late 19th and 20th centuries, subsequent innovators refined and enhanced this initial technology. Concurrently, advancements in synthetic rubber formulations, such as liquid silicone developed by chemists, spurred engineers to devise novel molding techniques. Notably, in the 1970s, James Watson Hendry introduced the gas-powered injection molding machine, revolutionizing manufacturing capabilities by markedly boosting production yields and making high-volume rubber molding more accessible and cost-effective.

Since the late 20th and early 21st centuries, automation has revolutionized rubber molding. Modern advancements blend CNC technology with CAD programming, enabling the rubber industry to efficiently produce large quantities of bespoke molded rubber products, with enhanced consistency, repeatability, and customization.

Rubber Molding Materials Process

Various types of rubber, ranging from natural rubber to synthetic variants like neoprene, foam rubber, EPDM, silicone rubber, and liquid silicone rubber, offer a wide array of molding possibilities. Synthetic rubbers not only share positive attributes with natural rubber but also possess distinct characteristics. They can be engineered to resist corrosion, withstand high temperatures and ozone exposure, remain inert to specific chemicals, and exhibit diverse properties such as rigidity, flexibility, durability, and strength. This enables the production of custom rubber parts that precisely match the requirements of different industries—from food-grade materials to high-performance elastomers for aerospace.

Natural Rubber

Natural rubber originates from the sap of specific trees, notably those within the Ficus genera. However, it is predominantly extracted from the Pará rubber tree (Hevea brasiliensis). Agricultural workers obtain the sap by tapping into the tree, akin to harvesting maple syrup from maple trees. Producers subsequently mix the sap with formic acid to induce coagulation. This raw rubber material contains latex, which may trigger allergic reactions, prompting some manufacturers to avoid its use in medical and food processing environments. Natural rubber is prized for its high elasticity, resilience, and abrasion resistance, making it ideal for tires, conveyor belts, and vibration isolators.

Neoprene

Neoprene, the pioneering synthetic rubber manufactured at scale by DuPont in the 1930s, consists of a versatile chloroprene polymer. It is widely utilized by manufacturers for shaping liners, gaskets, hoses, seals, and an array of household and gardening items. However, neoprene products are vulnerable to deterioration when exposed to chemicals such as acetic acid, turpentine, and iodine. Neoprene is valued for its weather resistance, flame retardancy, and flexibility, making it a frequent choice in automotive, marine, and industrial applications.

Foam Rubber

Foam rubber undergoes manufacturing with foaming agents, rendering it both flexible and air-filled. While it can be derived from various rubbers, polyurethane is the most common source. This material boasts impressive resilience—it can be twisted, scrunched, stretched, pushed, or pulled without damage. There are two primary variants: open cell and closed cell. Open cell foam features interconnected pores, promoting breathability and a softer feel. In contrast, closed cell foam presents isolated pores, enhancing its density by accommodating more pores within a given space. Think of it like this: open cell foam welcomes interaction with others through its connected pores, while closed cell foam prefers solitude, packing its pores closely together for greater density.

Open cell foam rubber finds its applications in crafting automobile trim, seat padding, pillows, and mattresses, as well as serving as packaging padding and for noise control. Conversely, closed cell foam rubber is employed in manufacturing thick automotive products, insulation, thermal management items, and protective gear such as elbow pads, knee pads, gloves, wetsuits, surgical scrubbers, x-ray positioning pads, and orthopedic braces. Interested in how foam rubber compares to other cushioning materials? Explore the differences between foam rubber and other elastomers for your specific project needs.

EPDM

EPDM, short for ethylene propylene diene monomer, boasts a range of exceptional qualities. It demonstrates remarkable resilience against steam, ozone, heat, and harsh weather conditions. Moreover, it offers superior electrical insulation. EPDM finds widespread application in automotive manufacturing, such as in electrical gaskets and door seals, as well as in building construction for roofing materials. Additionally, it plays a crucial role in the fabrication of engine cooling system hoses, weather stripping, and water-resistant seals. Wondering if EPDM is suitable for your outdoor or high-temperature project? Compare EPDM rubber to silicone and neoprene for weather-resistant applications.

Elastomers

Elastomers stand tall among polymers in industry, revered for their versatility across countless applications. These materials boast a unique duality: elasticity and viscosity, earning them the moniker of viscoelastic polymers. Among them, silicone rubber shines as a standout performer. Renowned for its exceptional qualities like high-temperature endurance and remarkable flexibility, silicone rubber remains a pinnacle of high-performance elastomers, particularly in demanding environments such as aerospace, medical, and electronics manufacturing.

Silicone Rubber

Silicone rubber, a synthetic compound composed of silicon, oxygen, carbon, and hydrogen, is available in both liquid and solid states. Solid silicone rubber stands out for its ease of sanitization, which has made it a favored choice in industries such as food processing, medicine, and biotechnology. Its molecular structure invariably includes an organic component linked to silicon and a siloxane backbone (a chain of alternating silicon and oxygen atoms). Both liquid and solid forms exhibit remarkable heat resistance, remaining stable even at temperatures up to 446℉. This thermal durability makes silicone rubber particularly suitable for applications like metal casting, high-temperature seals, and electrical insulation. However, it exhibits poor resistance to fuels and mineral oils. For applications involving these substances, fluorosilicone rubber serves as a viable alternative. Need high-temperature or medical-grade sealing solutions? Discover if silicone rubber is right for your requirements.

Silicone rubber starts off as a highly adhesive gel or liquid in its uncured state. To transform it into a solid form, it undergoes curing, vulcanization, or catalyzation. Typically, during manufacturing, this process occurs in two stages to achieve precise shaping, followed by an extended post-curing phase. Injection molding is another common application method for silicone rubber, supporting the fast production of complex, custom-molded parts.

Silicone rubber, ubiquitous in both industries and households, permeates our daily routines. This versatile material, known for its elasticity, finds myriad applications—from muffin pans and pot holders to medical devices, jewelry components, automotive connectors, and beyond. Silicone molds, crafted from RTV (Room Temperature Vulcanizing) silicone, undergo a chemical fusion of components triggering vulcanization. This process yields a non-stick, resilient, and pliable material, tailored to diverse molding needs across various sectors.

Properties of Silicone Rubber Molds

Silicone molds boast heat resistance, maintaining integrity at temperatures up to 302 °F without compromise. They excel in thermal and thermo-oxidative durability, offering reliable performance across a broad spectrum of operating temperatures.

They can withstand extreme cold, staying flexible and elastic even in temperatures as low as -76 °F to -94 °F due to their low glass transition temperature.

Silicone rubber, though flammable in its natural state, transforms into a flame-retardant and self-extinguishing material when supplemented with flame retardants.

- Silicone rubber boasts exceptional resilience against electrical discharge, maintaining stability even under high temperatures and frequencies.

Other distinctive characteristics include: their hydrophobic nature, their capacity to effortlessly detach materials from their surface, and outstanding protection from oxygen, ozone, and sunlight. They also have the capability to endure electromagnetic and particle radiation effortlessly, including UV rays, alpha and beta particles, and gamma rays, and exceptional non-stick and non-adhesive properties. They have reduced toxicity, clarity in optics, superb thermal insulation properties, a subdued response, exquisite compatibility with biological systems, and exceptional mechanical attributes.

How is Silicone Rubber made?

- Silicon atoms tightly bound within the silica compound must undergo separation to form silicone.

- Enormous quantities of quartz sand undergo heating at incredibly high temperatures, often reaching up to 3272 F°, to accomplish this task.

- Afterward, the silicone undergoes heating and multiple steps of mixing with methyl chloride. The resulting product, polydimethylsiloxane, undergoes polymerization and is subsequently distilled, making the polymerization of polydimethylsiloxane achievable.

- Various methods are employed to achieve this, tailored to the specific application of the end product. The catalyst is blended with necessary additives, such as pigments and the base silicone compound. Subsequently, it undergoes either extrusion or injection molding. The concluding stage of the manufacturing process involves curing.

Applications of Silicone Rubber

Here are several ways silicone rubber finds its place in industry:

- Aerospace – components of a space suit, seals, and insulating gaskets

- Automotive – gaskets and seals, spark plug boots, hoses

- Construction – coatings and sealants, window and door gaskets, expansion joints

- Electrical and electronics – adhesives and encapsulants, insulation, connectors, keyboards

- Food processing – food molds, tubing, baking mats, beverage hose linings

- Medical – medical instrument components such as seals, tubes, valves, catheters, prosthetics

- Recreation – goggles, mouthpieces, swim gear, fitness equipment grips

Rubber Molding Process Details

Understanding the rubber molding process is crucial for achieving optimal results in custom rubber manufacturing. The standard process follows these steps:

- Outline the specifications for the product to be molded, including the choice of material, precise dimensions, desired shape, and the required thickness.

- Create the die or mold cavity that will shape the raw rubber, often referred to as stock.

- Collect the stock.

- Insert the stock into your chosen machine.

- Let it cool and solidify.

- Remove the rubbery form.

- Complete any final touches required, such as trimming, finishing, or applying surface textures.

After the mold is removed, imperfections like seams might appear. In such instances, additional processing of the rubber product may be required. To enhance its aesthetic appeal or meet functional requirements, various finishes and textures can be incorporated into the final product. Curious about which process would yield the best quality for your application? Ask: Which rubber molding process is best for high-precision or high-volume production?

Rubber Molding Design

Manufacturers begin by envisioning the desired appearance, essential qualities, and dimensions of the part before selecting an appropriate rubber material. Once chosen, they employ computer programming to meticulously craft a precise design using CAD software. Simulation tools are often used to predict material flow, shrinkage, and potential defects, further refining the mold design.

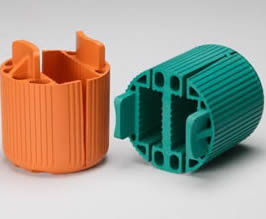

Custom rubber molding, particularly custom rubber injection molding, remains highly favored among customers who require unique part geometries or complex assemblies. Despite being more expensive than standard molding, custom molding proves more economical than alternative rubber manufacturing methods, such as machining or hand fabrication. With custom mold design, you gain the ability to create unique shapes, finishes, textures, tolerances, and dimensions tailored specifically to your application. Are you seeking a supplier for a complex, custom-molded part? Learn how to specify design details for custom rubber molding projects.

Rubber Molding Variations and Similar Processes

Rubber molding encompasses various techniques: injection molding, liquid injection molding, insert molding, compression molding, transfer molding, and blow molding. Although these methods share similarities, injection molding stands out as the most widely adopted for high-speed, high-volume, and precision manufacturing. An alternative to these methods is rubber extrusion, which is optimal for continuous profiles and simpler shapes.

Injection Molding

In the initial stage of the injection molding process, raw rubber material (stock) is gathered and deposited into a hopper positioned above a conveyance channel. From there, the stock is dispensed and guided through a channel equipped with a sizable rotating screw. As the stock progresses along the channel, it undergoes complete melting, facilitated by both internal heating elements and the friction generated by the screw’s rotation. At the channel’s terminus lies a mold cavity eagerly awaiting the infusion of molten rubber. Here, heat and pressure join forces, coaxing the liquid rubber to flow and conform meticulously to every curve and crevice of the mold. As the molten rubber cools and solidifies within the mold, it transforms into a form ready for extraction, securely holding the shape impressed upon it.

- The injection molding process stands out for its ubiquitous application, resilience, and intricate nature, owing to the diverse sizes and uses of its products.

- Material flows into mold cavities through plungers in mold halves.

- This method stands out due to its superior output efficiency, automation capabilities, and swift molding cycles.

- Materials from diverse sources can be simultaneously utilized without requiring any trimming of the product.

- Issues such as trapped air bubbles, flash, and sinks can be effectively mitigated through proper venting techniques.

- Thin-walled products benefit most from it, making it ideal for crafting small parts and automobile body panels.

Liquid Injection Molding

Liquid injection molding closely resembles traditional injection molding, distinguished primarily by the use of liquid raw materials. Unlike solid pellets, manufacturers employ liquid stock as the initial material. The process involves specialized machinery equipped with a metered pump to precisely regulate the flow of stock. This pump dispenses the liquid, allowing manufacturers to blend it with additives as needed. Once blended, a nozzle injects the mixture into a carefully shaped mold. Manufacturers then seal the mold tightly with clamps and apply precise heat and pressure to form the product. Liquid injection molding of rubber allows for rapid production without the need to liquefy stock, and resulting products often require minimal finishing.

- Liquid injection molding involves injecting liquid materials into cavities where they solidify to form products.

- Initially, raw materials are mechanically mixed, and once the product solidifies, it is ejected from the mold cavity.

- It involves a rigorous, time-efficient process ideal for crafting intricate designs with meticulous accuracy.

- This technique excels in mass production, utilizing thermal imaging technology to detect potential errors swiftly.

- It excels in fabricating gaskets, o-rings, keypads, and electronic contacts with unparalleled precision.

Insert Molding

Insert molding combines the flexibility of rubber and plastic injection molding by encapsulating non-rubber components, known as inserts, within molded rubber parts. This process is often used for creating items like knife blades, surgical tubes, electrical connectors, and threaded inserts, resulting in enhanced product durability and integration.

Compression Molding

Compression molded parts are crafted through a meticulous process: first, the manufacturer precisely weighs, measures, and preheats the raw material. Next, they insert it into a pre-formed mold cavity. The mold is then sealed shut, applying intense pressure to compress and shape the material, molding it into the desired form. Once set, the material is allowed to solidify and cool within the mold before being carefully extracted. After compression molding, excess material (flash) is typically removed through secondary processing. Rubber compression molding enables manufacturers to inexpensively create large, intricate products, although achieving consistent results can be challenging. Want to compare the cost-effectiveness of compression molding vs. injection molding? Explore which method suits your production scale and design complexity.

- Rubber preform is inserted into heated cavities where it conforms to create molds.

- The raw material may come as pre-measured pellets, granules, or powder.

- The cavities are sealed using heated plungers and subjected to pressures ranging from 15,000 to 20,000 psi.

- This cost-effective method operates at a moderate production rate.

- Ensure thorough cleaning of the cavities to prevent contamination.

- This process yields seals, o-rings, gaskets, automotive parts, and cushioning pads.

Transfer Molding

During transfer molding, manufacturers begin with a carefully measured rubber stock, known as a “preform,” which is placed into a cavity above the mold, called a “pot.” Using a heavy mechanical ram and heat, they press the preform, forcing it through a runner and gate system into the mold where it melts. The ram remains in position until the preform conforms completely to the mold’s shape. This method is prized for its ability to produce accurately molded rubber items and to bond rubber to metal surfaces seamlessly. Transfer molding is ideal for encapsulating electronics and creating high-precision, small components.

The plunger deposits the material into the heated cavity, which is subsequently cooled to conform to the mold’s shape.

- Waste resulting from mold compression is then manually trimmed, followed by cryogenic treatment, tumbling, or precision grinding.

- It boasts a condensed production timeline and stricter dimensional precision.

- This method excels in crafting diminutive, intricate, and highly detailed components.

Blow Molding

Rubber blow molding shapes hollow rubber products through a precise process. Initially, a parison (a tube-like plastic shape with a hole) or preform is used. The parison is clamped to a mold, into which compressed air is then blown through its hole. This inflation causes the rubber to expand and conform to the mold’s shape. Once cooled and solidified, the mold is opened to release the newly formed part. This process is commonly used to produce bellows, boots, and flexible tubing for automotive and industrial applications.

Liquid Silicone Rubber (LSR)

Liquid silicone rubber is a low viscosity, high purity thermoset elastomer that maintains its mechanical qualities throughout a wide temperature range, i.e., from -58 °F to 482 °F. This heat-cured elastomer is a great option if you want outstanding optical clarity and long-term endurance in a demanding environment (with high temperatures, UV exposure, etc.). LSR is also biocompatible, making it ideal for medical implants and baby products.

Injection molding stands alone as the sole method for creating liquid silicone rubber, undergoing heat-curing during the molding process. The foremost advantage of LSR lies in its capability to amalgamate multiple components into a single unit, facilitating substantial cost reductions. Moreover, liquid silicone rubber enables heightened production efficiency through the use of compact equipment and the elimination of material wastage.

Rubber Extrusion

Rubber components can also be manufactured using rubber extrusion as an alternative method. However, extrusion machines are somewhat constrained in their capabilities. Unlike molding processes that offer control over three axes through a cavity rather than a die, extruders are typically limited to the X and Y axes. This makes them better suited for producing simpler rubber items like baseboards, tubing, weatherstripping, or sheets. Curious about the differences between molded and extruded rubber? Compare rubber extrusion vs. rubber molding for your application needs.

Extrusion of Raw Material

- Extrusion involves shaping uncured raw material using a dye to form a consistent cross-sectional product.

- The raw material passes through an extruder equipped with screws to control temperature and rotation, facilitating the shaping process.

- After molding the product into its desired form, it undergoes a washing and cooling process using air or water before being precisely cut into its final shape.

- This efficient extrusion method is cost-effective, time-efficient, and allows for the mass production of goods.

- Maintaining tolerance criteria proves challenging, while per-part pricing fluctuates with the dye’s complexity.

- Ideal for crafting gaskets, tubing, and seals, it excels in production.

Product Calendering

- It involves a rapid and continuous process where several rollers compress the semi-liquid material into a solid sheet.

- Afterwards, these sheets are applied onto fabrics.

- Setting an ideal temperature for rollers is crucial to prevent overheating and adhesion issues.

- Additionally, product creeping is a notable concern during calendering processes.

- It serves to produce precise dye sheet cuts and thin material sheets.

Benefits of Rubber Molding

Rubber molding presents numerous advantages, particularly in contrast to alternative rubber forming methods. Initially, its versatility shines through: manufacturers harness a diverse array of rubber-based raw materials, facilitating the creation of intricate custom parts. Additionally, rubber molding excels in efficiency, significantly cutting down production timelines, making it particularly suited for large volume operations. Other key benefits include:

- Consistent, repeatable part quality, ideal for critical applications

- Ability to produce complex geometries and tight tolerances

- Reduced material waste compared to machining

- Wide range of material options, including food-grade, medical-grade, and high-performance elastomers

- Cost-effective for both low-volume prototypes and high-volume production runs

- Customization for color, durometer (hardness), and surface finish

- Excellent resistance to chemicals, temperature extremes, and UV exposure (depending on material selection)

Wondering how rubber molding can improve your product’s durability and performance? Contact a rubber molding expert to discuss your unique application requirements.

Choosing a Rubber Molding Manufacturer

When choosing a rubber molding service provider, you should think about these factors:

- What is the intended application? (e.g., automotive, medical, electronics, industrial, consumer products)

- What specific qualities are essential for my molded product, such as tensile strength, corrosion resistance, flexibility, and temperature resistance?

- Are there industry or regional standards that must be met, such as FDA, ISO, or RoHS compliance?

- How much customization is necessary for my project? (color, hardness, dimensions, tolerances, special features)

- What quantity of items do I need—prototype, small batch, or large-scale production?

- What budget and timeline constraints do I have?

- Does the supplier offer in-house design assistance, prototyping, and secondary operations (trimming, bonding, assembly)?

- Can the manufacturer provide references or case studies in your industry?

By understanding these answers, you can 1) identify the specific product and service offerings to focus on during your research, and 2) engage in more effective discussions with potential manufacturers. We recognize the abundance of rubber molding manufacturers and suppliers in the market, varying in quality. To assist you in navigating this landscape, we’ve compiled a comprehensive list of reputable manufacturers you can rely on. Explore their profiles to gain deeper insights into each. Select three or four that pique your interest the most, and reach out to them with your specific requirements. Initiate meaningful conversations about production, compare their responses afterward, and choose the provider whose services, including customer support, best meet your needs. Contact them again to kick-start your project!

Ready to start your search? Compare top-rated rubber molding companies, request quotes, and review their certifications and capabilities to ensure the perfect fit for your project.

Check out our Polyurethane Molding website to learn more about custom urethane molding solutions, applications, and manufacturing options for your next project.

What industries use rubber molding products?

Rubber molding products are used in a variety of industries, including medicine and healthcare, electronics, aerospace, automotive manufacturing, transportation, sports and recreation, industrial machinery, EMI shielding, sound management, and energy production.

What are the common materials used in rubber molding?

Common materials for rubber molding include natural rubber, neoprene, foam rubber (such as polyurethane), EPDM, silicone rubber (liquid or solid), and liquid silicone rubber (LSR). Each material offers unique properties suitable for different applications, such as temperature resistance, flexibility, electrical insulation, and chemical resistance.

What are the main rubber molding processes?

The main rubber molding processes are injection molding, liquid injection molding, insert molding, compression molding, transfer molding, and blow molding. Each process has specific advantages and is chosen based on the part’s geometry, production volume, and material used.

What are the benefits of rubber molding compared to other forming methods?

Rubber molding offers versatility in material selection, enables the creation of complex shapes with tight tolerances, and is efficient for both low-volume prototypes and high-volume production. It reduces material waste, delivers consistent part quality, allows customization in color and properties, and can produce parts with excellent chemical, thermal, and UV resistance, depending on material choice.

How is silicone rubber different from other rubber materials?

Silicone rubber is a synthetic material known for its outstanding heat resistance (up to 446°F), flexibility, non-stick properties, biocompatibility, and excellent electrical insulation. Unlike some rubbers, it maintains stability across a wide temperature range and is commonly used in medical, food processing, electronics, and high-temperature applications.

What should I consider when choosing a rubber molding manufacturer?

Key factors include the intended application, required material properties (tensile strength, temperature and chemical resistance), regulatory standards (such as FDA or ISO), customization needs, production quantity, budget and timelines, design and prototyping support, and the manufacturer’s experience with similar products or industries.

What are the differences between rubber molding and extrusion?

Rubber molding uses a mold cavity to form complex, three-dimensional shapes, ideal for intricate and detailed parts. Extrusion pushes raw material through a die to create products with a consistent cross-sectional profile, making it suitable for simpler shapes like tubing, weatherstripping, and baseboards. Molding is preferred for custom, precise parts; extrusion is best for continuous lengths and simpler forms.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services