Rubber overmolding is a process that has been gaining popularity in recent years due to its versatility and effectiveness in creating durable, high-quality products. It involves the injection of rubber material onto a substrate or insert, which creates a seamless and durable bond between the two materials. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to military applications we build trust by being responsive to your needs.

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

All your typical molded rubber parts & more! Our custom rubber molding expertise includes mold conversion, non-conductive parts, injection molding, compression molding, transfer molding, die cutting & extrusions, plus cryogenic deflashing, trimming and curing. Low to medium volumes on time & budget!

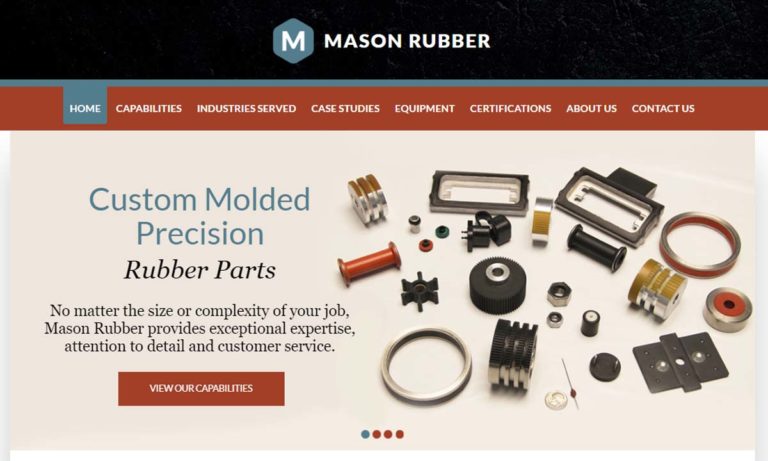

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both domestic and offshore services are available.

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO 9001:2015 & AS 9100-D. Collaborative product customization available. Request free samples on site.

National Rubber was founded in 1997 with the values of variety, consistency, quality, open communication, and timely delivery at its core. Today, we stay true to these values by taking each one of your specifications into consideration, and working with you through every step of the manufacturing process. Call us today for more information!

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Overmolding Companies

Rubber overmolding is used in a wide range of applications, from consumer products to industrial equipment, and has many advantages over other manufacturing methods.

The Process of Rubber Overmolding

In general, rubber overmolding involves using a two-part mold, designed to create the specific shape and design of the final product. The substrate or insert is placed into the mold, and the rubber material is injected around it, creating a seamless bond between the two materials. This process can be done using a variety of machines, including vertical injection molding machines, transfer molding machines, and insert molding machines. Each machine has its advantages and applications, and companies may choose the one that best fits their specific needs.

Benefits of Rubber Overmolding

Rubber overmolding has a wide range of benefits that make it a popular choice for many manufactured products. Rubber overmolding products' key benefits include improved grip, enhanced shock absorption, and increased durability. Additionally, rubber overmolding can create items with a watertight seal and resistance to chemicals and high temperatures.

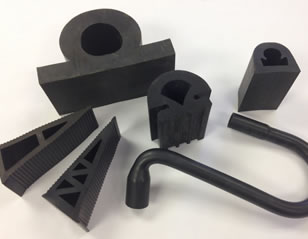

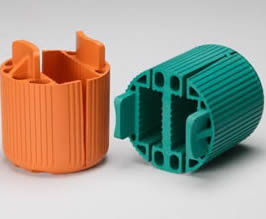

Likewise, the rubber overmolding process itself provides many benefits over other production methods. To begin with, rubber overmolding has the ability to create complex shapes and designs that are difficult to achieve with traditional molding techniques. This is possible because rubber overmolding allows for the combination of two or more materials with different properties, creating parts that have unique features and characteristics. For example, a hard plastic component can be overmolded with a soft rubber material to create a strong and comfortable part to grip. Furthermore, rubber overmolding also allows for customization and personalization of parts. Colors, logos, and other markings can be easily added to parts during the overmolding process. This is particularly useful for branding purposes or to differentiate products in the market. Finally, rubber overmolding offers versatility. It can be used with a variety of materials, including plastics, metals, and other elastomers. This means that rubber overmolding can be used in many industries, from automotive and aerospace to medical and consumer products. Overall, rubber overmolding provides many benefits that make it a popular choice for manufacturers. Its ability to create complex shapes and designs, customization options, versatility, and improved properties make it a valuable technique for creating high-quality parts that meet the needs of various industries.

Applications of Rubber Overmolding

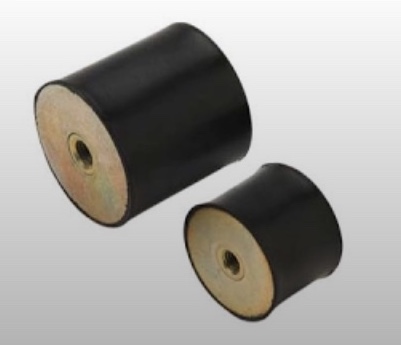

Rubber overmolding is used in a wide range of industries, including automotive, aerospace, medical, and consumer products. In the automotive industry, rubber overmolding is used to create durable and slip-resistant grips for steering wheels and shift knobs. In the aerospace industry, rubber overmolding is used to create seals and gaskets that can withstand extreme temperatures and pressures. In the medical industry, rubber overmolding is used to create ergonomic and hygienic handles for medical devices.Rubber overmolding can be used to produce various types of industrial equipment, such as seals, gaskets, grips, and vibration-dampening components.

In addition to the applications previously discussed, there are many other ways in which rubber overmolding is used. In the healthcare industry, for example, rubber overmolding is often used to create medical devices such as catheters, grips for surgical instruments, and disposable plastic parts that require a soft touch. In the electronics industry, meanwhile, rubber overmolding is used to create a variety of parts, including keypads, switches, and plugs. Additionally, the sports and fitness industry uses rubber overmolding to create grips for sports equipment such as golf clubs, baseball bats, and tennis rackets. Finally, in the construction industry, rubber overmolding is used to create parts such as grips for power tools and safety equipment.

Considerations Regarding Rubber Overmolding

Despite its many advantages, rubber overmolding does have some potential considerations to account for . One of these is the potential for defects such as voids, flash, and delamination. These defects can occur due to a variety of factors, such as improper mold design, incorrect material selection, or processing issues. To prevent defects, companies must implement effective quality control measures and optimize their process parameters to ensure that the material flows evenly and consistently throughout the mold cavity.

Improving Overmolding Processes

To combat these considerations, companies that perform rubber overmolding are taking an active role in improving their manufacturing processes. This includes the use of advanced mold design and simulation software, the implementation of lean manufacturing principles, and the adoption of new technologies such as automated inspection systems and robotics. These efforts have resulted in improved efficiency, reduced waste, and increased customer satisfaction.

The Future of Rubber Overmolding

Looking towards the future, rubber overmolding is likely to continue to be a popular and effective manufacturing method. Advances in materials science and manufacturing technology are expected to further improve the quality and consistency of overmolded products, while new applications in emerging industries such as renewable energy and wearable technology are likely to drive demand for rubber overmolding. By continuing to innovate and improve their processes, companies that perform rubber overmolding can remain competitive and provide value to their customers for years to come.

Choosing the Right Rubber Overmolding Company

To ensure you have the most beneficial result when purchasing rubber overmolding from a rubber overmolding company, it is important to compare several companies using our directory of rubber overmolding companies. Each rubber overmolding company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or to request a quote. Review each rubber overmolding business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple rubber overmolding companies with the same form.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services