There are three standard rubber molding styles: compression, transfer, and injection. Rubber components are formed into practical items via the process of rubber molding. The tools that enable this technique are rubber molders. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to military applications we build trust by being responsive to your needs.

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

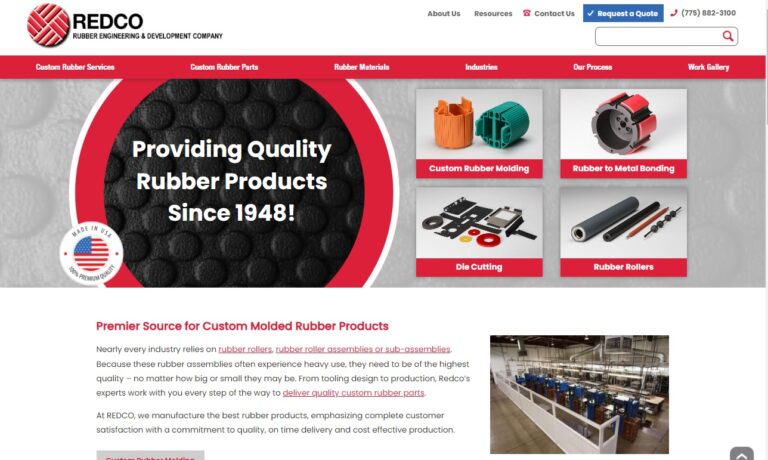

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

All your typical molded rubber parts & more! Our custom rubber molding expertise includes mold conversion, non-conductive parts, injection molding, compression molding, transfer molding, die cutting & extrusions, plus cryogenic deflashing, trimming and curing. Low to medium volumes on time & budget!

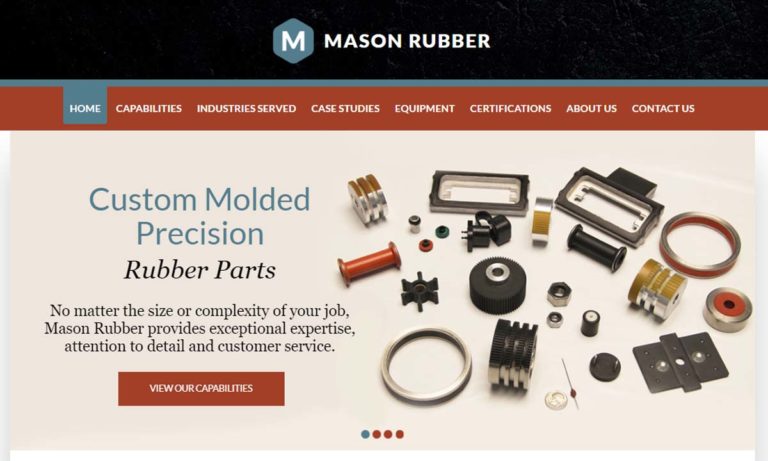

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both domestic and offshore services are available.

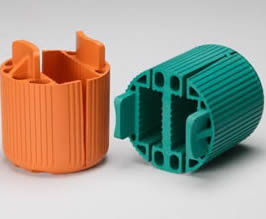

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO 9001:2015 & AS 9100-D. Collaborative product customization available. Request free samples on site.

National Rubber was founded in 1997 with the values of variety, consistency, quality, open communication, and timely delivery at its core. Today, we stay true to these values by taking each one of your specifications into consideration, and working with you through every step of the manufacturing process. Call us today for more information!

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Molder Companies

Rubber Molded Products: Versatility, Applications, and Selection Guide

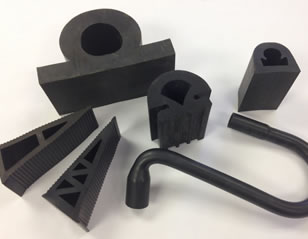

Rubber molded products are essential across nearly every industry, offering unmatched versatility, durability, and customization options. From automotive and aerospace to medical, electrical, and consumer goods, molded rubber components serve critical functions in both standard and custom applications. Molded rubber goods are prized for their ability to solve vibration, sealing, insulation, and protection challenges in industrial and commercial environments.

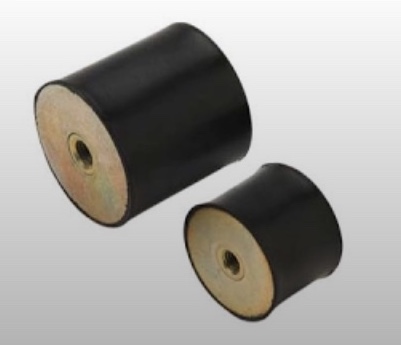

In machine-related manufacturing processes, controlling vibration is crucial for safety and performance. Components such as rubber washers, rubber bushings, and rubber vibration isolators are specifically engineered to absorb shock and dampen movement. This protects workers, prevents equipment damage, and extends machinery lifespan. Rubber grommets are another popular product, widely used in electrical enclosures, automotive body panels, and home appliances. A rubber grommet is designed to shield wires, cables, or tubing as they pass through holes, providing environmental protection, abrasion resistance, and noise reduction.

Common Types of Molded Rubber Products

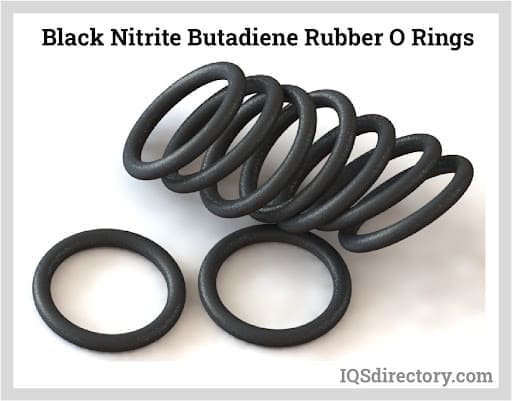

- O-rings & Seals: Ensure leak-proof connections in pumps, valves, and hydraulic systems.

- Gaskets: Maintain pressure and prevent contamination in engines, pipes, and electronic assemblies.

- Bushings & Mounts: Isolate vibration, reduce noise, and support heavy loads in vehicles and machinery.

- Rubber Caps & Plugs: Protect sensitive components during shipping or storage.

- Custom Molded Parts: Designed for specific applications in industries such as aerospace, energy, and food processing.

Are you searching for custom rubber molded components for a unique application? Learn how to select the right rubber molder company.

Rubber Molders: Capabilities, Customization, and Industry Expertise

Rubber molders are specialized manufacturers dedicated to producing high-quality molded rubber products through advanced techniques and state-of-the-art technology. Most rubber molding companies offer both standard product lines and custom rubber molding services that cater to unique project requirements. The ability to custom design and rapidly prototype new parts gives businesses a competitive edge, especially in industries where innovation and performance are key.

- Custom Rubber Molders: Provide engineering support, material selection guidance, and fast-turnaround prototyping for bespoke rubber parts.

- High-Volume Production: Leverage automated molding processes to deliver consistent quality and cost-effective pricing for large orders.

- Industry Certifications: Many leading rubber molders hold ISO 9001, IATF 16949, or FDA certifications to meet strict quality standards in automotive, medical, and food-grade applications.

Considering a custom solution? Explore the different rubber molding processes and their benefits.

Key Considerations When Selecting a Rubber Molder

Choosing the right rubber molding partner can significantly impact product quality, project timelines, and overall cost. Modern rubber molding equipment integrates automation, robotics, and precision controls to optimize the production of both standard and custom molded rubber products. When evaluating rubber molding companies, consider the following factors:

- Material Expertise: Does the molder offer a wide range of elastomers—such as natural rubber, EPDM, silicone, nitrile (NBR), fluorocarbon (FKM/Viton), and SBR—suitable for your environment and performance needs?

- Design & Engineering Support: Can the company assist with CAD modeling, material selection, and prototyping to optimize your part design?

- Certifications & Compliance: Is the molder certified to produce components for regulated industries (e.g., medical, automotive, aerospace)?

- Production Capabilities: Does the facility support both low-volume prototyping and high-volume manufacturing with tight tolerances?

- Quality Assurance: Are in-house testing, inspection, and traceability protocols in place to ensure consistent results?

- Lead Times & Scalability: Can the company meet your delivery schedule and adapt to changing order volumes?

- Value-Added Services: Look for secondary operations such as assembly, bonding, kitting, or packaging.

Not sure which material or process is best for your application? Compare rubber molding methods and materials here.

Applications of Rubber Molding: Industrial, Commercial, and Specialized Use Cases

Rubber molding technology enables the production of components that are used in a wide array of industries and product categories. The flexibility and customization available through precision rubber molding allows manufacturers to address highly specific engineering challenges. Common applications include:

- Automotive: Seals, gaskets, vibration isolators, bushings, and weatherstripping for vehicles.

- Medical Devices: Biocompatible seals, diaphragms, and tubing for diagnostic and therapeutic equipment.

- Electronics: Grommets, keypads, insulators, and overmolded connectors to protect sensitive electronics.

- Industrial Manufacturing: Rollers, pads, conveyor belts, and custom bumpers for equipment and assembly lines.

- Aerospace: High-performance seals and vibration-damping parts for aircraft and spacecraft.

- Consumer Goods: Appliance feet, grips, and waterproof buttons for home and office products.

- Oil & Gas: Sealing solutions and elastomeric couplings for exploration and refining equipment.

- Renewable Energy: Weatherproof gaskets and pads for solar, wind, and battery systems.

Looking for a rubber molded part for a specific industry? Browse qualified rubber molders by market expertise.

The Benefits of Rubber Molding: Performance, Design Freedom, and Cost Efficiency

When evaluating rubber product manufacturing methods, molding stands out for its ability to deliver complex geometries, enhanced material properties, and superior consistency. Compared to processes like extrusion or die-cutting, molding offers several unique advantages:

- Complex Part Design: Intricate shapes, undercuts, and detailed surface textures can be achieved with high repeatability.

- Material Versatility: A variety of rubber compounds and elastomers can be selected to meet requirements for temperature resistance, chemical compatibility, flexibility, and durability.

- Prototyping & Customization: Rapid prototyping enables the development and testing of new designs, while production tooling supports low to high-volume runs.

- Performance Optimization: Tailor properties such as hardness (durometer), tensile strength, and elongation to specific end-use conditions.

- Cost-Effectiveness: Automated production lines and multi-cavity molds reduce per-part costs for both standard and custom rubber products.

- Quality & Consistency: Modern molding technology ensures minimal variation between parts, critical for industries with stringent quality requirements.

Wondering which molding process is right for your project? Compare injection, compression, transfer, and liquid injection molding options below.

Rubber Molding Processes: Methods, Advantages, and Material Compatibility

Injection Molding

Rubber injection molding is the leading process for high-volume production of precision rubber components. In this method, solid or pre-mixed synthetic rubber is heated and injected into a closed mold cavity at high pressure. Automated equipment ensures uniform fill and fast cycle times, making it ideal for producing complex shapes, thin-walled parts, and multi-material components. Learn more about rubber injection molding.

- Best For: Automotive seals, electrical grommets, medical-grade components, and consumer products.

- Advantages: High production speed, tight tolerances, minimal waste, and excellent repeatability.

- Materials: Natural and synthetic rubbers, including EPDM, NBR, silicone, FKM, and neoprene.

Compression Molding

Compression molding is widely used for mid- to low-volume production and for manufacturing large or thick-walled rubber parts. In this process, pre-measured rubber stock is placed into a heated mold cavity. The mold is closed and pressure is applied, causing the material to flow and take the shape of the cavity. After curing, the finished part is removed and trimmed if necessary.

- Best For: Large gaskets, seals, bushings, and pads for industrial, marine, and construction applications.

- Advantages: Lower tooling costs, suitability for large parts, and compatibility with a wide range of elastomers.

- Materials: Natural rubber, SBR, EPDM, neoprene, and custom compounds.

Molding by Liquid Injection (LIM)

Liquid Injection Molding (LIM) utilizes low-viscosity liquid silicone rubber (LSR) or other liquid elastomers. A metering pump precisely measures and mixes the components before injecting them into the mold. LIM is favored for applications requiring medical-grade, food-grade, or optical clarity parts, as well as those demanding high automation and low cycle times.

- Best For: Medical device seals, baby products, keypads, and overmolded electronics.

- Advantages: High purity, clean processing, fast cycle times, and minimal post-mold finishing.

- Materials: Liquid silicone rubber (LSR), fluorosilicone, and specialty liquid elastomers.

Transfer Molding

Transfer molding bridges the gap between compression and injection molding, offering versatility for combining rubber with inserts such as metal, fabric, or plastic. Pre-formed rubber is loaded into a pot above the mold cavity, then pressed and transferred into the cavity by a plunger or ram. This process enables the encapsulation of metal components and the precise molding of intricate shapes.

- Best For: Bonded rubber-to-metal parts, electrical insulators, and precision diaphragms.

- Advantages: Supports insert molding, excellent for intricate geometries, and good dimensional control.

- Materials: Standard and specialty rubbers, including nitrile, EPDM, and high-performance elastomers.

Have questions about which molding method is best for your application? Request expert guidance from top rubber molding companies.

Choosing the Proper Rubber Molder Company: Steps for Success

Selecting the right rubber molder is a critical decision that impacts your project’s success, from product quality to budget and delivery timelines. Here’s how to ensure you partner with a manufacturer that meets your needs:

- Define Your Requirements: Clarify your part’s function, performance criteria (such as temperature and chemical resistance), and desired material properties.

- Use a Trusted Directory: Compare at least 5 companies from our rubber molder directory. Each business profile highlights capabilities, facilities, certifications, and experience in your industry.

- Request Information & Quotes: Use company contact forms to ask about material recommendations, tooling options, lead times, and pricing. Share drawings or prototypes for more accurate quotes.

- Review Quality and Compliance: Check for ISO, IATF, FDA, or other relevant certifications. Ask about in-house testing and process controls.

- Evaluate Customer Support: Strong engineering support, fast communication, and willingness to collaborate are key signs of a reliable partner.

- Use Website Preview Tools: Leverage our proprietary website previewer to get an at-a-glance view of each molder’s specialties and recent projects.

- Submit a Unified RFQ: Save time by using our RFQ form to contact multiple companies with the same requirements—compare responses to find the best fit.

Ready to get started on your molded rubber product? Browse our directory or request a quote today.

Frequently Asked Questions About Rubber Molding

- What is the difference between compression and injection molding?

Compression molding is generally best for large, simple parts and lower volumes, while injection molding suits complex, high-volume production with tighter tolerances. - Which rubber compounds are available for molding?

Most rubber molders offer a broad range of elastomers, such as natural rubber, silicone, EPDM, nitrile, neoprene, FKM/Viton, and specialty blends tailored to your environment and application. - How do I choose between standard and custom molded rubber parts?

Standard parts are cost-effective for common applications, but custom molding allows for unique geometries, materials, and performance attributes that off-the-shelf solutions cannot provide. - What industries benefit most from molded rubber products?

Automotive, medical, aerospace, industrial machinery, construction, electronics, and consumer goods are major sectors using molded rubber components for sealing, vibration control, and protection. - How do I ensure quality and compliance?

Work with molders that offer robust quality programs, material traceability, and certifications relevant to your industry (such as ISO 9001 or FDA registration).

Start Your Rubber Molding Project Today

No matter your industry or application, partnering with a trusted rubber molding manufacturer ensures you receive expertly engineered parts, reliable performance, and long-term value. Take advantage of our comprehensive resources to:

- Compare leading rubber molders by specialty, location, and capabilities

- Request personalized material and process recommendations

- Obtain fast, competitive quotes for your custom or standard rubber parts

- Access expert engineering support for design, prototyping, and production

Have more questions? Contact us for expert guidance on your next molded rubber project, or explore our educational resources to learn more about rubber molding technology, materials, and best practices.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services