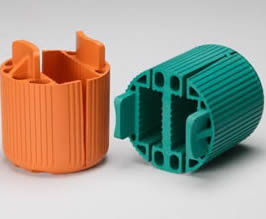

Rubber is a generic term that encompasses many extremely elastic polymers typically referred to as synthetic rubbers and natural rubber, derived from the Pará rubber tree. Rubber manufacturers use numerous varieties of rubber to make products essential to daily living. For instance, natural rubber is utilized to make several marine items, conveyor belts, and windshield wipers. In addition, rubber producers use synthetic materials to produce numerous auto parts, including flooring, mats, window and door profiles, belts, and hoses. Rubbers can be either natural or synthetic when making tires. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to military applications we build trust by being responsive to your needs.

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

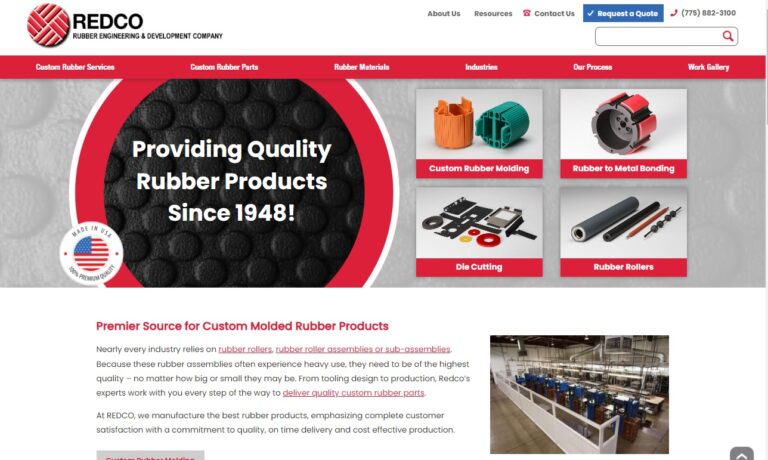

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

All your typical molded rubber parts & more! Our custom rubber molding expertise includes mold conversion, non-conductive parts, injection molding, compression molding, transfer molding, die cutting & extrusions, plus cryogenic deflashing, trimming and curing. Low to medium volumes on time & budget!

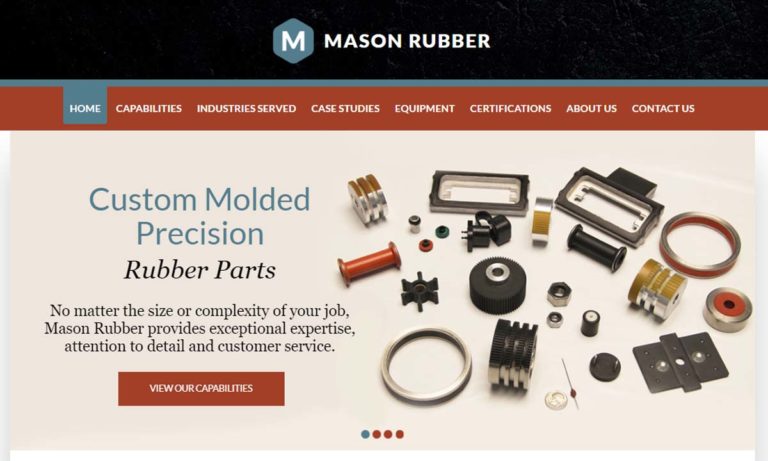

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both domestic and offshore services are available.

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO 9001:2015 & AS 9100-D. Collaborative product customization available. Request free samples on site.

National Rubber was founded in 1997 with the values of variety, consistency, quality, open communication, and timely delivery at its core. Today, we stay true to these values by taking each one of your specifications into consideration, and working with you through every step of the manufacturing process. Call us today for more information!

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Companies

The Origins of Rubber

The first synthetic rubber was created in Germany in 1909, and as rubber costs skyrocketed, later versions were employed in both World War I and succeeding years. Finally, synthetic rubber usage entered the mainstream in World War II. This increased usage was directly due to the enormous demand for rubber needed to make tires for war machines and the prohibitively expensive and insufficient supply of natural rubber.

The Process of Harvesting Rubber

The main method for obtaining natural rubber is tapping rubber trees, which release latex, a sticky material resembling milk. The latex is collected, then processed to create rubber. Natural rubber can either be vulcanized or left uncured. Rubber is heated during the vulcanization process, after which peroxide, bisphenol, or sulfur may be added to change its flexibility, strength, or resistance to stresses.

Vulcanized rubber has more uses than other ones. Shoe soles, hockey pucks, domestic clothes wringers, rubber boots, and pump housings are a few items that rubber producers create utilizing vulcanized rubber. In addition, they produce adhesives, insulation, cement, friction tapes, and crepe rubber, which is used to insulate clothing and footwear using uncured rubber.

The Uses of Rubber

Rubber's relative gas impermeability is another fantastic quality that makes it a popular material for making things like balloons, air hoses, sports balls, and cushions. Additionally, as soft rubber products have a high level of electrical resistance, they are frequently employed inside protective footwear like gloves and shoes. The fabrication of electrical instruments, such as components for radio sets, meters, and telephone housings, uses hard rubber just as frequently.

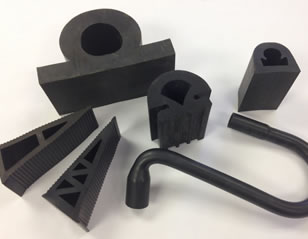

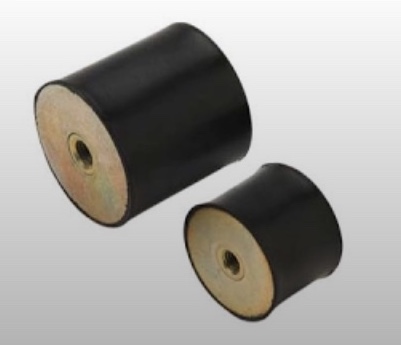

Rubber producers frequently employ rubber to create diving equipment, rain boots, rain jackets, umbrellas, medical and chemical tubing, and the lining of railroad tank cars, storage tanks, and processing equipment since it is water and fluid resistant. Large and small gaskets, latex gloves, shock absorbers, and specialty equipment mounts are examples of other rubber items. Even extrusion, rubber bonding, and rubber molding operations can utilize rubber.

Factors to Consider When Selecting a Rubber Manufacturer

An interested party will approach a rubber producer with knowledge and willingness to hear customer requirements for the greatest outcomes. When discussing its application, customers should communicate to rubber manufacturers the amounts of stress and strain they want to place on their product and the temperature range in which it will operate.

The required strength and, to some extent, the rubber product's elasticity will depend on the anticipated levels of stress and strain. Additionally, because elasticity changes with temperature, and a manufacturer must design a product to account for that, it is crucial to indicate projected temperature averages.

Machinery Used by Rubber Manufacturers

Extruder Machines

Rubber items are made via a technique called rubber extrusion. The procedure involves applying high pressure to an extrusion machine to push synthetic or natural rubber material through a formed die. Typically, rubber that has not been vulcanized and is soft is used. First, the workpiece is shaped while it is soft and malleable, and then it is vulcanized to harden it into a usable finished product.

Two basic pieces make up a rubber extruder machine. Compounds are supplied into the extruder as the raw material is pushed along a conveyor by a heated shearing screw. The material is heated and softened to make it flexible as it passes along the conveyor. The shearing screw applies pressure to the softened material, forcing it into the die, where it is given its final shape.

Calendering Machines

The rubber material is fed through horizontal rollers inside calendering machines. Frequently, they are employed in the rubber friction or combining process, which involves fusing rubber sheeting with another material or fabric.

Advantages of Manufactured Rubber

Without the rubber tires on modern vehicles, driving would be challenging. In addition, numerous other items would disappear, including rubber boots, flooring, surgical gloves, and balloons for kids' parties. The ability to benefit from a strong, long-lasting, and wonderful material is undoubtedly why rubber manufacturing is so well-liked today. Rubber manufacturing is environmentally friendly, which is another benefit. Many things harm the environment in the modern world.

Non-biodegradable materials, like tin and plastic, are dumped in rivers and oceans, tainting their crystal-clear freshness and seriously harming the environment. However, rubber is a wonderful material that doesn't harm the environment. While the world is unquestionably getting increasingly polluted and uninhabitable every year due to the manufacturing of other products, rubber manufacturing is very common in the modern world because rubber is harmless and biodegradable. People can make a variety of goods with the material produced by the rubber industry.

Choosing the Right Rubber Manufacturer

To make sure you have the most positive outcome when selecting a rubber manufacturer, it is important to compare at least 5 manufacturers using our rubber manufacturer directory. Each rubber manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rubber manufacturer company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple rubber manufacturer companies with the same message.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services