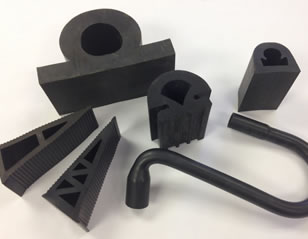

Rubber injection molding is the process by which raw rubber material is injected into a metal mold cavity to create a useful product. Vulcanization, or curing, is a chemical reaction that applies pressure to cross-link the rubber’s polymer chains. Injection rubber molding is the most popular rubber molding technique. Manufacturers create customized projects, complex pieces, and big-volume production runs using rubber injection molding. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to military applications we build trust by being responsive to your needs.

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

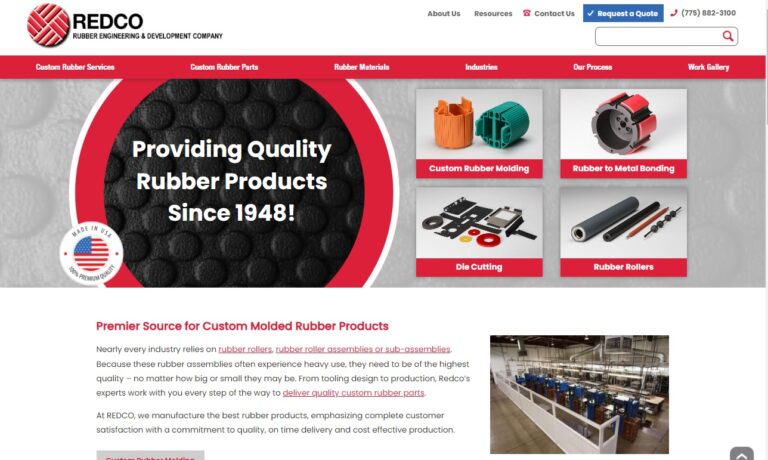

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

All your typical molded rubber parts & more! Our custom rubber molding expertise includes mold conversion, non-conductive parts, injection molding, compression molding, transfer molding, die cutting & extrusions, plus cryogenic deflashing, trimming and curing. Low to medium volumes on time & budget!

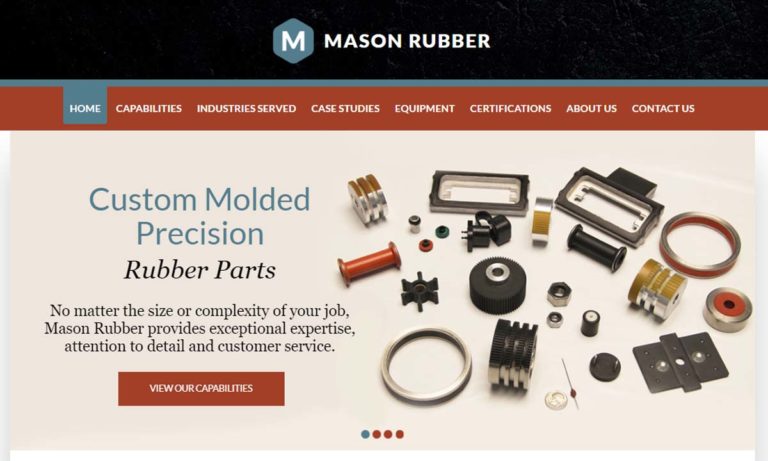

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both domestic and offshore services are available.

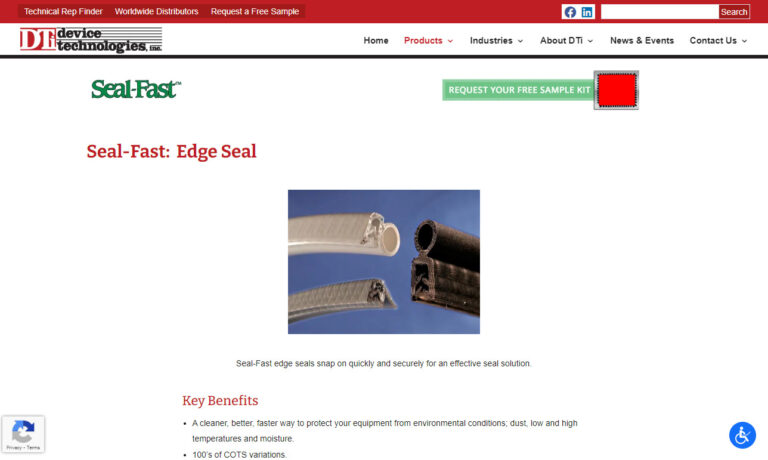

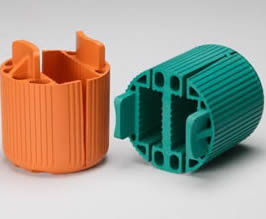

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO 9001:2015 & AS 9100-D. Collaborative product customization available. Request free samples on site.

National Rubber was founded in 1997 with the values of variety, consistency, quality, open communication, and timely delivery at its core. Today, we stay true to these values by taking each one of your specifications into consideration, and working with you through every step of the manufacturing process. Call us today for more information!

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Injection Molding Companies

Injection Molding Process

The injection molding process allows for acute precision. First, manufacturers melt the raw rubber. The rubber flows in liquid form into the mold cavity through a barrel or nozzle. The mold is clamped tightly to prevent or reduce flashing.

In injection molding, chemical reactions harden the polymer chains inside the raw rubber. Long polymer chains are forced to cross-link to prevent them from moving independently. As a result, the rubber material stretches or shrinks as the force is applied or released. The rubber forms intricate shapes.

The engineers must consider the placement of the separating line while injection molding to ensure it has a minimal draft angle. The mold's design is regarded as the cornerstone of part development. The finished mold is then converted into a metal mold. Sometimes, beryllium-hardened aluminum, hardened steel, or copper are used to create and manufacture molds. After the mold is created and cast, it is tested to make sure it accurately conforms to the original dimensions.

Types of Rubbers Used for Injection Molding

- Natural rubber

- Silicone

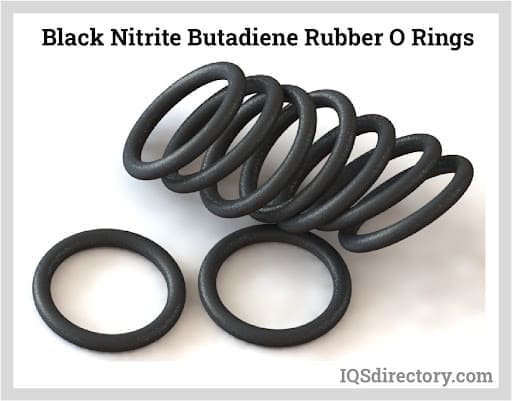

- Nitrile rubber

- Fluorosilicone

- Liquid silicone rubber

- Urethane

- Butyl

- Fluorocarbon

Products Made with Rubber Injection Molding

Rubber Grommets

Rubber grommets are rings placed around metal apertures to shield the opening. Rubber grommets are often used for wiring.

Rubber Plugs

Rubber plugs are typically used to protect edges and joints on machinery. In addition, rubber plugs can be used to conceal wires that are a part of an intake wiring system under specific circumstances. There are many rubber plugs, including the connector, the T, the plus, and the washer.

Vacuum Cups

Vacuum cups are another name for rubber suction cups. They serve as a handling mechanism for objects with flat surfaces like metal sheets, glass, tubes, wood panels, or manufactured things. There are many types, styles, and sizes of rubber suction cups. However, bellows and flat rubber suction cups are the two primary varieties.

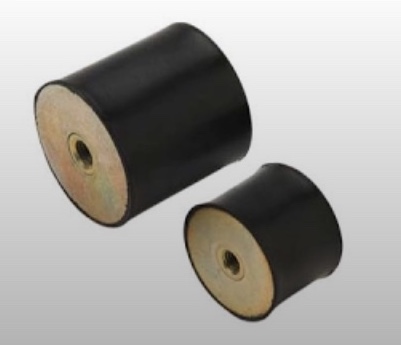

Rubber Isolators

Rubber isolators are used the most often in industries. They shield equipment and home appliances from vibration-related harm. They are also in charge of maintaining the machinery's level and position while stationary. Mounts, bumpers, leveling pads, bushings, and shock mounts are examples of rubber isolators. Controlling vibrations is a crucial component of equipment operation.

Advantages of Rubber Injection Molding

- High accuracy

- Enables more complex designs

- Eliminates performs in a short cycle period

- Less rubber and flash waste

- More durometer shore choices

- Excellent for requirements requiring high volume production

Disadvantages of Rubber Injection Molding

- Higher setup expenses

- Smaller quantities of parts can be expensive

- Costlier equipment and tools

Choosing the Proper Rubber Injection Molding Company

To make sure you have the most beneficial outcome when selecting a rubber injection molding company, it is important to compare at least 4 to 5 companies using our rubber injection molding directory. Each rubber injection molding company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each rubber injection molding company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple rubber injection molding companies with the same form.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services