Baseboards made of rubber that have been molded or extruded are used to cover the joint between floors and walls. Rubber is an excellent material for baseboards since it can be more impact-resistant and scratch-resistant than wood or plastic, and if it does become damaged, it can be easily replaced. In institutional, industrial, and residential structures, rubber baseboards can be installed for solely practical reasons or to improve the visual appeal of a living or working area. Read More…

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production solutions for rubber molding. From aerospace to medical, food processing to military applications we build trust by being responsive to your needs.

If you have a need custom rubber molding for products with a fast turnaround, Britech Industries is the company you need to call. We do molded, extruded and die cut rubber – of various products and in the colors and compounds you need.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

Rubber molding is what we do best. We believe in offering our very best to all customers no matter how large or small. For over 65 years we have pushed the boundaries of what we do and continue to improve our products and customer service every day.

REDCO Rubber Engineering & Development is your complete source for rubber molding products, including rubber rollers, die-cut gaskets, and custom rubber products to suit your application.

All your typical molded rubber parts & more! Our custom rubber molding expertise includes mold conversion, non-conductive parts, injection molding, compression molding, transfer molding, die cutting & extrusions, plus cryogenic deflashing, trimming and curing. Low to medium volumes on time & budget!

Mason Rubber is a full-service organization assisting in the designing or reverse engineering of custom product to fulfill your production requirements.

Kent Rubber Supply leverages our experience, innovation and continuous development to ensure our customers get the best products. We specialize in small to large batch production runs of molded rubber parts, allowing us to offer ultimate customization when it comes to a wide variety of specs. Our products vary in shapes, sizes and wall thicknesses in materials such as PVC and urethane. Both domestic and offshore services are available.

Spring-Fast Grommets with fusion bonded nylon & a polymer cushion prevent wire chafe & give you best in class performance, 49% install savings & a 9.5x efficiency improvement. The nylon clad metal substrate snaps on with finger pressure & self locks - eliminating adhesives & the old slow & costly gluing process. It is used widely used in across the OEM & contract manufacture sectors. ISO 9001:2015 & AS 9100-D. Collaborative product customization available. Request free samples on site.

National Rubber was founded in 1997 with the values of variety, consistency, quality, open communication, and timely delivery at its core. Today, we stay true to these values by taking each one of your specifications into consideration, and working with you through every step of the manufacturing process. Call us today for more information!

Jet Rubber Company, employee-owned, offers custom molded rubber and rubber to metal components. They offer rubber molding in a wide array of standard rubber products as well as custom options for those more complex and difficult jobs.

More Rubber Baseboard Companies

How Rubber Baseboards are Made

Rubber baseboards can be plain and simple or decorated with unique patterns and designs. In either scenario, they shield classroom walls from being harmed by desk leg impact. They shield factory walls from scuffs brought on by contact with moving parts or machines.

Rubber baseboards can be made from either synthetic or natural rubber, depending on the application. For baseboards that will be used in demanding environments, like factories, synthetic rubbers such as EPDM can provide better levels of impact resistance as well as other features of strength and durability. In other settings where durability and strength may not be as critical, basic baseboards can be created from reasonably-priced natural rubber goods and still function effectively.

Types of Rubber Baseboards

The different types of rubber baseboards include:

Thermoplastic Vinyl (TV)

Although it is one of the three varieties of rubber, thermoplastic vinyl (TV) is a composite material manufactured almost entirely of polyvinyl chloride (PVC). The TV material is heated, extruded, and then molded into the final product since it is malleable at high temperatures.

TV offers several advantages. It can be recycled since it can be heated and cooled repeatedly without losing quality. It is a cost-effective alternative for wall base because it is the least expensive of the three varieties of rubber. However, compared to other varieties of rubber, TV is more difficult to handle and install, and it might develop white stress lines or discoloration when shaping corners.

While TVs are more prone to obvious gouges and nicks than other types of rubber, the matte coating can help cover scuffs. TV is a good, affordable option for wall base, accessories, flooring, and stair systems in low-traffic areas (emergency stairways, secondary stairwells, and light commercial applications).

Thermoplastic Rubber (TP)

Vinyl and rubber are combined to form thermoplastic rubber (TP). TP is heated, extruded, and formed into a finished product just as TV. Additionally, it does not lose quality when heated or cooled, allowing for recycling. The wall base needs to be acclimated on-site for at least 24 hours before TP installation. Similar to TV, stress lines and discoloration may emerge while constructing corners. Additionally, it has a matte surface to help nicks and gouges blend in. The "best" option for rubber wall base is TP because it contains rubber. When money is still an issue and there is medium to medium-heavy traffic, TP should be used.

Thermoset Vulcanized Rubber (TS)

Thermoset vulcanized rubber is TS rubber. It is a rubber that includes virgin fillers and additives combined with either synthetic or natural rubber. The vulcanization of heat and pressure improves the materials' elasticity, tensile strength, hardness, and weather resistance. TS includes the most rubber of the three varieties.

One of the main distinctions between the various forms of rubber is the chemical process of vulcanization. Because it doesn't contain PVC, TS is better for the environment and could earn LEED points. The most durable rubber is Type TS, but it is also the priciest option. Because of the uniform composition of TS, nicks and gouges are less common than in TP or TV. Furthermore, TS is resistant to shrinking and stress signs.

Advantages of Rubber Baseboards

- Durability: Rubber flooring, whether in the form of sheet or tile, endures exceptionally well in high-traffic areas over extended periods of time, making it a wise investment.

- Comfort: Rubber's comfort underfoot is another advantage. Rubber flooring has a pleasant feel to it and is naturally non-slip. As a result, it is a safer choice when there are many people on the streets.

- Acoustics: Rubber is quieter overall since it is a little softer than some of the other hard surface items. Rubber's ability to absorb sound is especially helpful in big, empty spaces where there can be an echoing of noise.

Choosing the Correct Rubber Baseboard Manufacturer

To make sure you have the most positive outcome when purchasing rubber baseboards from a rubber baseboard manufacturer, it is important to compare at least 4 to 5 companies using our list of rubber baseboard manufacturers. Each rubber baseboard manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rubber baseboard business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple rubber baseboard businesses with the same form.

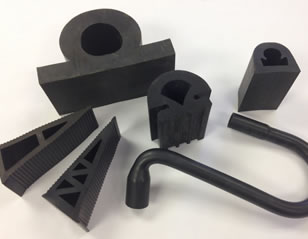

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

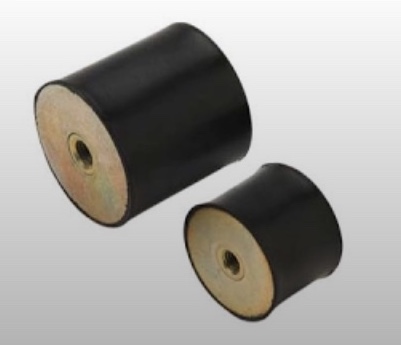

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

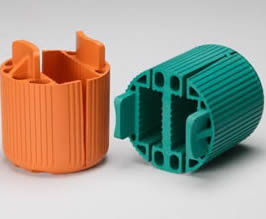

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services